Thomson-Shore book manufacturer finds perfect fit in purchase of Ann Arbor's Bessenberg Bindery

Jon Buller of Bessenberg Bindery now will train a new generation of specialty binders at Thomson-Shore.

Tom Perkins | For AnnArbor.com

Former Bessenberg Binding ownerJon Buller hit a winning streak to remember in late October.

Around then he struck a deal for his custom binding company to be purchased by Dexter-based specialty publisher Thomson-Shore Inc. The next day, a buyer made an offer on the downtown Ann Arbor building that housed Bessenberg. Buller had feared the building would be tough to sell, but both deals were as good as they could have come.

That same week, Buller's eldest son was married and another son received his doctorate. He joked that he tried buying Lotto ticket, but apparently his good fortune had expired.

“That was the best week of my life,” Buller said.

By the end of the year, Thomson-Shore had finalized the purchase of the downtown Ann Arbor bindery’s name and assets for an undisclosed price and moved the entire company into its own 300,000-square-foot Dexter facility.

The move establishes Michigan's only custom commercial case bindery business as a division of Thomson-Shore, which employs more than 200 people and expects growth this year even as the book industry changes. And now Buller is there to help train a younger generations of binders.

Both sides are more than pleased with the arrangement and how the sale played out.

In June 2009, Buller, 64, put his building at 215 N. Fifth Ave. on the market in anticipation of selling Bessenberg upon retirement. He explained moving the business out of the “high rent district’ would have made it a little more attractive to prospective buyers.

But in February 2010, Thomson-Shore President Kevin Spall heard at a dinner party that the business was up for sale. He had met Buller a year prior and was “captivated” by the product he stood for and what his business was all about, which was very much in line with Thomson-Shore’s philosophies.

While in Ann Arbor a week after the dinner party, Spall dropped by Bessenberg to inquire about the business. When learning that it was only the building for sale, Spall invited Buller to lease space in Thomson-Shore’s building.

But as the pair discussed their common interests in the book world, Buller says, it quickly became evident combining their essentially related, specialty businesses was the best route. Thomson-Shore offers high quality offset printing for everyone from independent authors to the largest publishing houses. Their runs are generally low count and they emphasize quality customer service.

Having an in-house binder that specializes in high quality work for low counts makes sense on a financial level for both companies. Spall added that there is a “softer, more philosophical reason” for the sale as well.

“We can take a craft that is dying and has been under pressure for years and take it and not just preserve it, but cultivate it and grow it with exposure to our customers,” he said.

Buller was pleased to find a buyer who saw his company's value.

“Here is an ongoing, larger organization that saw value in what we’re doing, understood how we could augment the service they provide their clients, and I’m now here as an employee of Thomson-Shore, working toward integrating the bindery - what I worked on for 35 years - into what they’re doing,” Buller said.

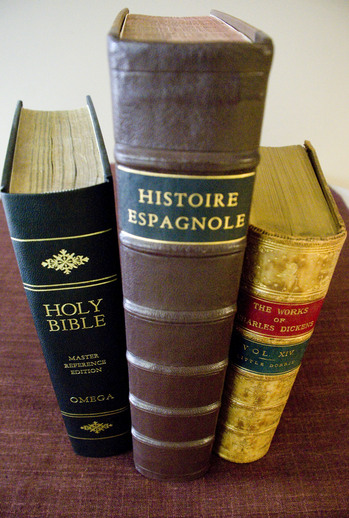

Three books Bessenberg recently bound include a bible for an Ypsilanti minister; "The History of Spain", which was made in 1586 for the King of Navarre; and a set of Dickens' works for a book collector in Marshall

Tom Perkins | For AnnArbor.com

“This is an opportunity for this business to continue well after I leave,” he added. “To me, that was important. You spend your life building up what you hope is a little institution and the idea is to have it last after your demise.

"They are willing to do that and I’m very happy for it.”

Buller originally told Spall he wanted to delay the sale for fear of being unable to find a buyer for the building, which would force him to pay the mortgage out of his own pocket.

But Buller changed his mind in late October and told Spall there was no reason Thomson-Shore’s business should be held up. They closed on the deal.

The next day, the building’s buyer, Jonathan Rye, put in his offer. By late December, all of Bessenberg’s equipment were settled into the new Dexter location.

“They sort of picked us up, the personnel and equipment, and dropped us off here and now we’re doing what we did for all those years downtown,” Buller said.

What Bessenberg has done since opening in 1975 is offer custom book binding, and the company is one of the last binders in the country to do so. If a publisher wanted a small run of leather-bound books for an author or to commemorate a special title, Bessenberg could handle such a request. Their prices range from $35 to bind a dissertation to $450 to bind one book with a fancier cover.

Spall said he once pulled a book off their production line before it had its cover, took it to Buller and asked what would make a good cover. Buller explained what leathers were popular at the time the book was published in the early 20th century and suggested going with that.

Spall sees a market for customers who will appreciate that kind of knowledge and Bessenberg’s craftsmanship.

“There’s this general, collective movement toward commodity products, and part of this is the expectation that as more and more products go the way of the commodity, there will be more emphasis on the super high-end quality items, books being one of them,” Spall said.

Spall said Thomson-Shore is one of the few printers who has refined manufacturing methods to provide high quality work on a run of 1,000 books, for example, and do it cost effectively. That ensured survival as the market has generally gravitated toward commodity printers.

The company was founded in 1972 and is now employee owned. About 225 employees work in their Dexter facility, and Buller said one of the reasons he found Thomson-Shore attractive was the decision-making structure, in which everyone has a voice.

Spall and Buller are pleased that several employees in Dexter are ready to learn the craft. As Spall pointed out, Buller is one of the few people in the country from who one can learn 400 year old Italian leather binding techniques.

“We’ve got employees who are chomping at the bit to go in there and start learning and training,” he said.

Comments

Caferacer

Sat, Jan 29, 2011 : 1:32 a.m.

Great article Tom! This seems to be a wonderful marriage of old and new school all to the benefit of book publishers and readers. Well done say I!

Dan

Wed, Jan 26, 2011 : 12:23 p.m.

Jon and his colleagues have done great work for me on individual bindings as well as when I published a deluxe edition of a book. It's great to see that their work will continue past Jon's retirement.

hypsi

Mon, Jan 24, 2011 : 9:24 p.m.

iPads and E-readers are not as "green" as you may think: How Green Is My iPad <a href="http://www.nytimes.com/interactive/2010/04/04/opinion/04opchart.html" rel='nofollow'>http://www.nytimes.com/interactive/2010/04/04/opinion/04opchart.html</a> Few snippets from the article: "The adverse health impacts from making one e-reader are estimated to be 70 times greater than those from making a single book." "An e-reader also requires 79 gallons of water to produce its batteries and printed wiring boards, and in refining metals like the gold used in trace quantities in the circuits. "

racer

Sun, Jan 23, 2011 : 8:12 p.m.

Andy Jacobs...Really well thought out post. Do you realize Washtenaw County has the highest concentration of book manufacturers in the country. The printing industry is one of the strongest sectors in this area. It accounts for many jobs in the region. Maybe you are not aware that trees (for paper) are a renewable resource. Like corn, soy beans, and wheat, trees for the construction and paper industry are farmed and renewed.

Old Bones

Sun, Jan 23, 2011 : 5:01 p.m.

What a great article! This is an art form that is almost lost, along with typecasting and letterpress operation. It's so nice to see that there are still those out there who care enough to keep this skill alive.

glacialerratic

Sun, Jan 23, 2011 : 3:58 p.m.

"As Spall pointed out, Buller is one of the few people in the country from who one can learn 400 year old Italian leather binding techniques." Should be "from whom." Who edits this?

John Alan

Sun, Jan 23, 2011 : 3:52 p.m.

I am glad things worked out for Jon. He worked hard and deserved to have some good event rolling his way....

Soothslayer

Sun, Jan 23, 2011 : 3:02 p.m.

Traditional print is dead and for good reason (waste of natural resources). Long live the eBook & iPad!

DFSmith

Sun, Jan 23, 2011 : 2:09 p.m.

Good for Jon. I wonder if he will still be taking small jobs- like one-off book repair or rebinding type of jobs.

Bill Sloan

Sun, Jan 23, 2011 : 1:06 p.m.

What a great and positive story. It's nice to know that there are flourishing alternatives to big box stores, huge supermarkets, and big business takeovers and that young people are interested in learning and reserving traditional, highly skilled crafts. A perfect example of Governor Snyder's concept of "gardening" in the business world.